SP Pump

The SP pump is submersible, space-saving, and easy to install. It also has high efficiency and motor protection built-in. SP pumps have high reliability across the range. They are all corrosion-resistant stainless steel, and they suit many applications.

Features and Benefits

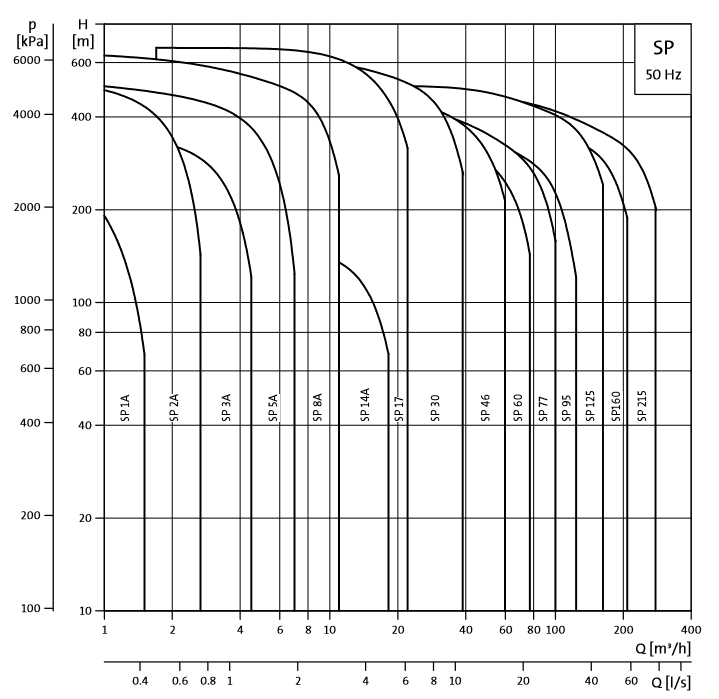

A wide pump range

We have energy-efficient submersible pumps from 1 to 280 m³/h. The pumps come in many sizes – and each size has optional stages to match any duty point.

High pump efficiency

Pump efficiency is often ignored compared to the price. But the smart user will see that price differences are not important for water supply economics compared to pump and motor efficiencies.

Example

Pumping 200 m³/h at 100 m head for 10 years will save EURO 60,000 if a pump/ motor with 10% higher efficiency is chosen and the price is EURO 0.10 per kWh.

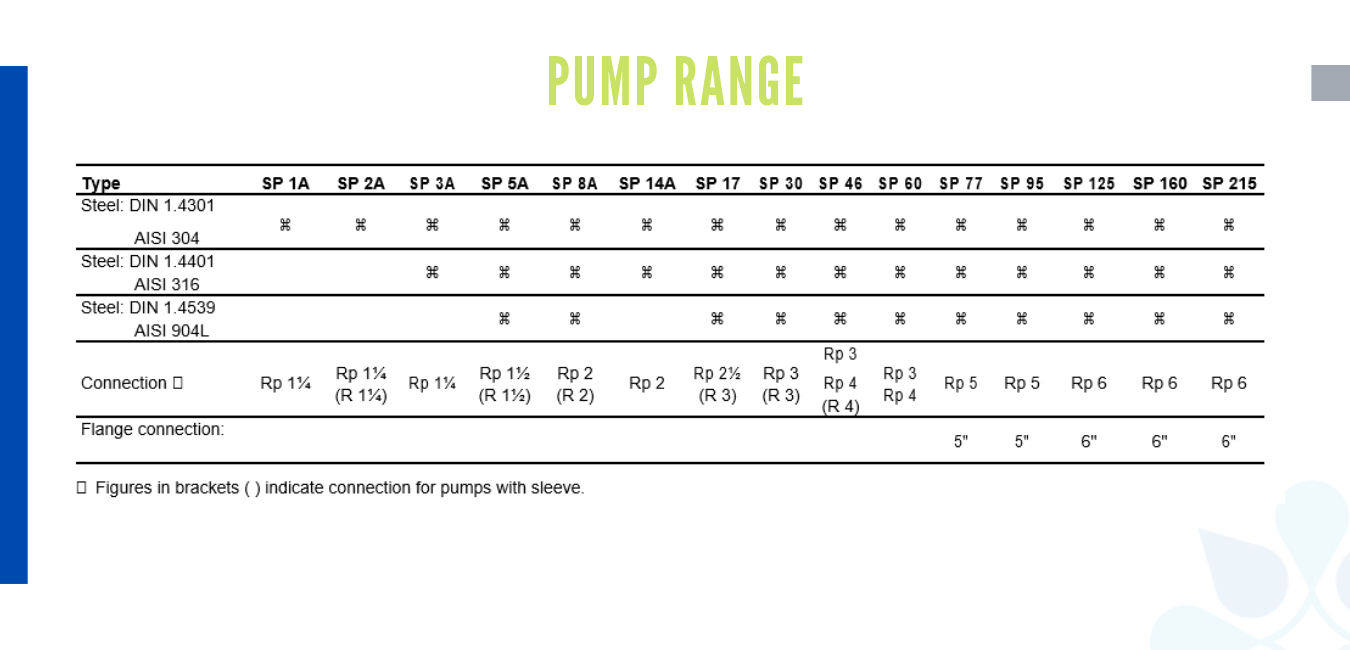

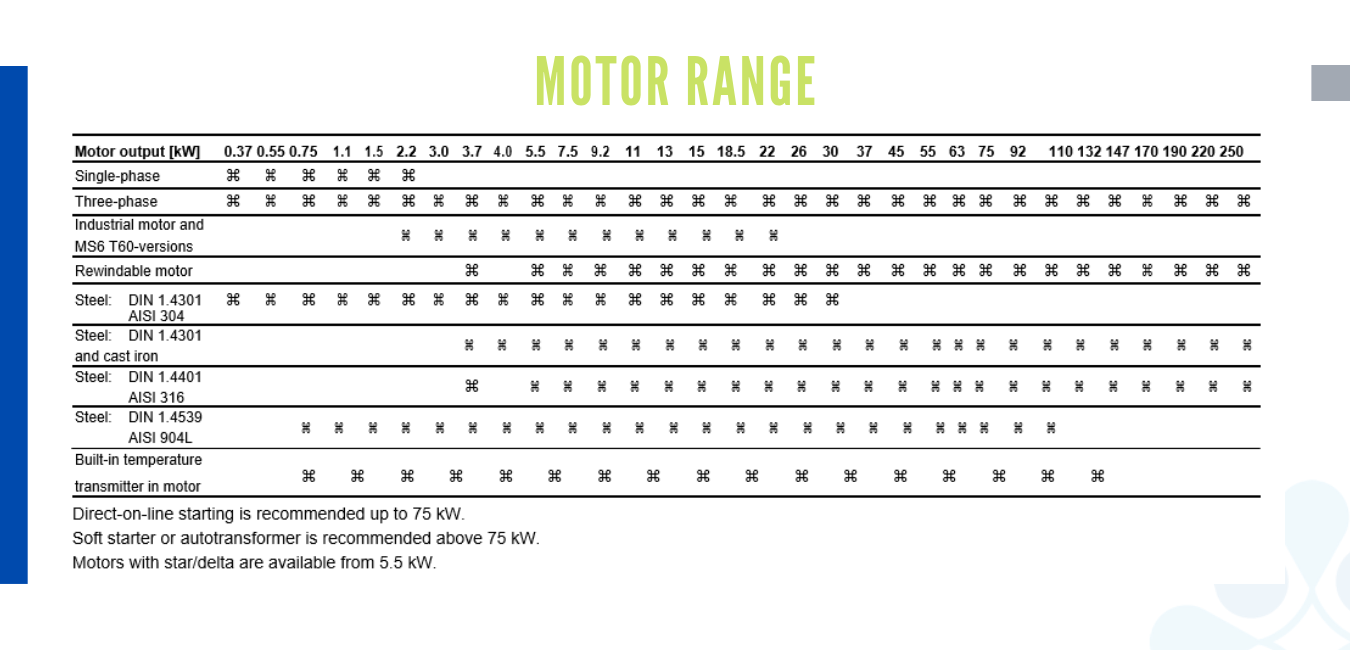

Material and pumped liquids

We have a full range of pumps and motors that are all stainless steel to DIN W.-Nr. 1.4301 (AISI 304) as standard. This gives good wear resistance and less corrosion risk when pumping normal cold water with a low chloride content.

Alternatively, we have a full range of zinc anodes for cathodic protection. This may be good for sea water applications. For slightly dirty liquids with oil, for example, we have a full range of stainless steel SP NE pumps to DIN W.-Nr. 1.4401 (AISI 316) with FKM rubber parts.

Low installation costs

Stainless steel means light weight that makes pumps easy to handle and lowers equipment costs and installation and service time.

Bearings with sand channels

All bearings are water-lubricated and have a square shape that lets sand particles, if any, leave the pump with the pumped liquid.

Inlet strainer

The inlet strainer stops particles over a certain size from entering the pump.

Non-return valve

All pumps have a reliable non-return valve in the valve casing that stops back flow when the pump stops. Also, the non-return valve closes quickly and lowers the risk of harmful water hammer. The valve casing has optimal hydraulic properties to lower the pressure loss across the valve and increase the pump efficiency.

Priming screw

All 4″ pumps have a priming screw. This stops dry running, because the priming screw makes sure that pump bearings are always lubricated. The large SP pumps have semi-axial impellers that provide priming automatically. But for all pump types, if the water table drops below the pump inlet, the pump and motor are not protected from dry running.

Stop ring

The stop ring protects the pump from damage during transport and up-thrust when starting. The stop ring, which works as a thrust bearing, limits axial movements of the pump shaft.

SP Pump Performance Range

The SP pumps are suitable for the following applications:

- Raw water supply

- Irrigation systems

- Groundwater lowering

- Pressure boosting

- Fountain applications

- Mining applications

- Off-shore applications

Get SP Pump From PT GLS

PT Gapura Liqua Solutions reflect our commitment to control the product quality by working closely with our strategic business partners, mostly leading components manufacturing firms in the field of water treatment, waste water treatment, desalination, and resources recovery.

You will guarantee product originality, advisory for your water system, and taking care by our skilled engineer to meet your business goals. Contact us now!